If using a pump and tank system, ensure that the water is clean and the pump is fully submerged.

At this point, turn off the power and perform step When using a Peltier control device, please ensure that the water supply is turned on. NOTE: If step 4 is performed before step 3, an alarm will sound and the instrument controller display will read optical init. For AR1000/550/500 systems equipped with an ETC, turn on the power to the ETC electronics box. Turn on the Power to Rheometer Switch the power button, located on the rear of the electronics control box, to the ON position. Locate another gas source, attach it to the gas port on the rheometer, and then attach bearing lock while the air bearing is floating. NOTE: If air supply is interrupted while bearing lock is off, DO NOT TURN the DRIVE SHAFT, this will cause damage to the bearing. NOTE: For an AR2000 system with a drive-shaft slide lock, please ensure that the drive-shaft slide lock is pulled-out. Once the bearing lock is removed, make sure that the spindle rotates freely. Remove the black bearing lock by holding it in place while turning the draw rod knob at the top in a counter-clockwise direction. TA Instruments, 109 Lukens Drive, New Castle, DE 19720, USA 1.

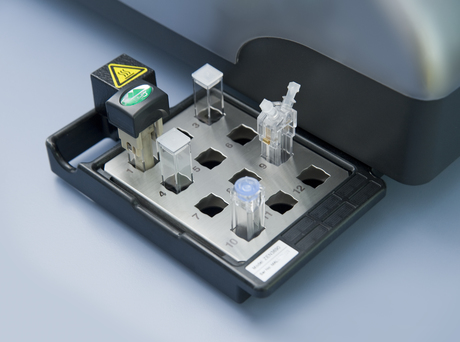

#Malvern zetasizer underfilling cell series

1 INTRODUCTORY GUIDE TO USING AN AR SERIES RHEOMETER USING RHEOLOGY ADVANTAGE SOFTWARE* (VERSIONS 4.1) Fred Mazzeo, Ph.D.

0 kommentar(er)

0 kommentar(er)